Its equipped with induction cooling water cooling the oil pump is connected with the oil sending lubrication and cooling bearing. They operate at inlet temperatures varying from ambient dehumidified air for sensitive products to more than 1100 o F 600 o C for robust products.

Dryers Spin Flash Dryers Anhydro

5 - 2 sees and the final moisture is generally in the constant rate drying zone.

. The drying process usually is completed in 0. Mechanism prior to design work is strongly recommended. 5 - 2 sees and the final moisture is generally in the constant rate drying zone.

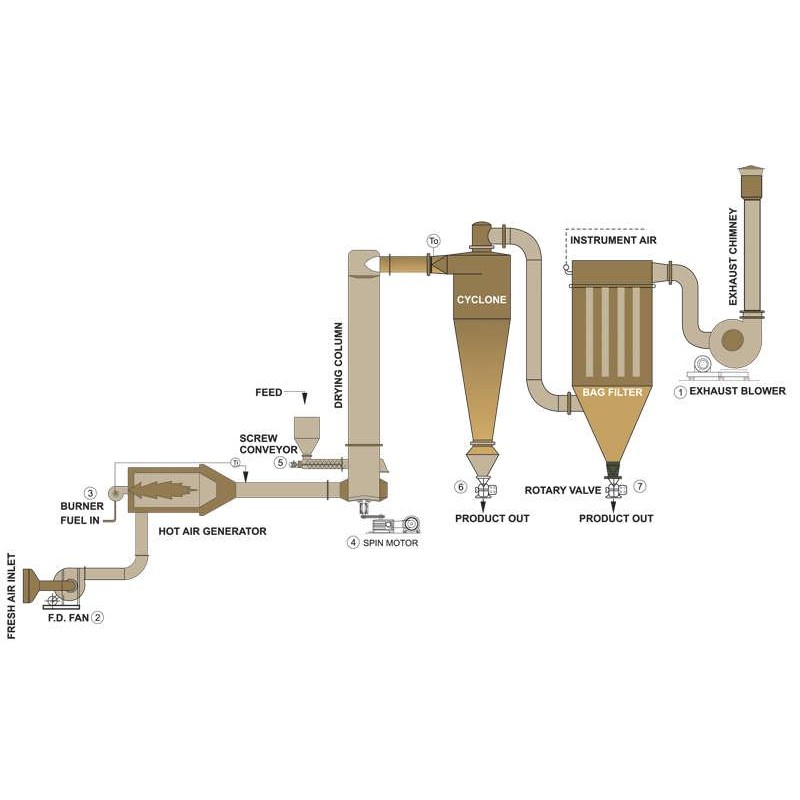

Ad Vevor Committed To Supplying An Incredible Assortment Of Excellent Quality Products. The Design of Spin Flash Dryer JIANG BinCHAI Ben-yinPENG Li-hua MIAO ShuaiDONG Xian-huaZHANG Lei Shandong Tianli Drying Equipment CoLtdJinan 250014China This paper introduces structure drying principles of Spin Flash Dryer and calculation and determination of related parameters. The version installed for this particular process utilizes a feed screw though some other installations have a pumped feed.

Gas-solid mixture is tangentially fed at the bottom of the dryer. Various types of spin flash dryers designs are available based on uniform non uniform particle size of the feed. With quite a few Spin Flash Dryer installations In India.

Spray driers classified on basis of air and feed flow are designed to enhance thermal efficiency of the system. The clean thermal medium heated by the heat source enters the drying chamber in a tangential form forming a powerful vortex swirling airflow with the mechanical agitation mechanism. Whenever possible to apply heat direct to the material to be dried Rotary Dryers of the Direct Heating Design are used.

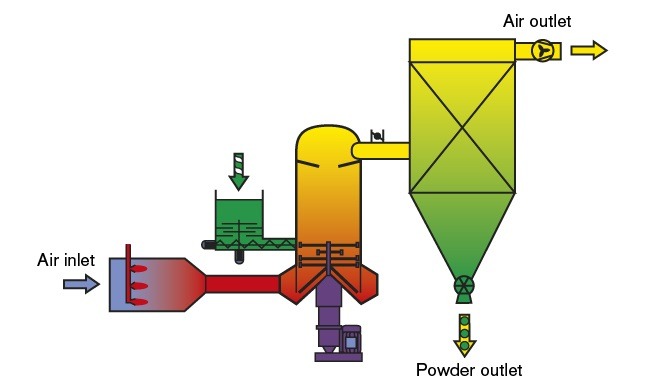

Product KeywordsXSG Spin Flash DryerSpin Flash DryerFlash Dryer Category Flash Dryer and Airflow Dryer Series Description The hot a ir enters into the bottom of the dryer in tangent directionUnder the driving of the stirrera powerful rotating wind area is formedThe paste s tate materials enter into the dryer through the s crew. The main shaft adopts the half ring type design the. Therefore the challenge is to operate the flash dryers at design capacity and more.

Which air flow is best suited for which process is determined by the properties of the material involved. 3 Additional energy demands. Wet product is introduced into the air stream through a Venturi feeder.

Flash dryers have been used to dry products in many industries including agrifood chemical mineral. G 1 AV1000W1W2100W1 3AV100055-12100-55AV956. Design and numbers of internal baffles are adapted for each.

Besides its economic importance that application is representative of those where the product is combustible so that the drying needs to be conducted in an inert. This two step procedure involves disintegration about feed as well as drying of fragment feed. Rotary Dryer Calculation Volume calculation.

Flash drying is a continuous process with the dryer being either directly or indirectly fired. V15ms Dry Air Density. A broad range of feed materials including powders cakes granules flakes pastes gels and slurries can be processed.

For evaporating moisture from concentrates or other products from plant operations Rotary Dryers are designed and constructed for high efficiency and economy in fuel consumption. 1 Thermal inefficiencies in the dryer. Rotary Dryer Kiln.

For slurries pastes or sticky materials backmixing of the wet feed with a portion of dry product to produce a suitable. Spin Flash Drying is used in applications like Dryer Minerals General Chemicals and Pigments. The drying process usually is completed in 0.

Power for solids transport vacuum pumps and air fans. In drying of wet solids the following main factors which essentially are used in process design calculation of dryers should be defined in accordance with mass and heat transfer principles process conditions and drying behavior. Steam generation efficiency steam leaks and mains losses.

Flash dryer with a more compact equipment. The simple spin flash dryer is designed to handle materials that can be suspended directly in air. The paper presents a basic model of the flash drying process as it is applied in a number of industrial applications and illustrates this by means of a particular application.

The wet material is metered into the drying chamber by a feeder pulverized and dried by stirring and vortex flow. The drying of subbituminous coal. We Can Make Sure Free Shipping Nationwide And 30 Days Free Return You Can Have A Try.

If the throughput of the dryer is 60 kg of wet product per hour drying it from 55 moisture to 10 moisture the heat requirement is. The spin-flash dryer SFD is a pneumatic dryer capable of handling a large variation of feed composition. Span Flash Dryers manufactured by TRIVENI IS used for Spin Flash drying technology of high-viscosity products pastes and filter cakes Widely acclaimed by customers In a variety of industries all over India this process provides a faster and more energy-efficient alternative to spray drying.

Cyclonic dryer is composed of a cylindrical body with a set of internal conical baffles. The main components in the Spin Flash plant are a feed system the patented drying chamber and a bag filter. The drying chamber has a rotor in its conical base which creates an efficient drying air flow pattern.

The flow direction of hot air and feed and flow loop of the system. They are inherently cocurrent dryers with the hottest air contacting the wettest product. The sealing device has superior performance.

Our spin flash dryer eliminates the pollution and the technology reaches to the international advanced level. Spray dryers are generally classified based on two criteria. Spin flash drying generates powder from the feed that is gelatinous or viscous in nature filter or paste cake.

Our Spin Flash dryers are designed for continuous drying of cohesive and non-cohesive pastes and filter cakes as well as high-viscosity liquids. The spin flash dryer consists of a feed system with a vat and agitator for buffering and fragmenting feed product. Vπr²L314x11²x2491m 3 82m 3 fulfill requirement Rotary Dryer Energy Balance.

Calculation of the quantity of water to be evaporated is explained below with a sample calculation. 2 Thermal inefficiencies in the utility heat supply system. In the SFD particles are dried in an agitated fluidized bed and ejected when dry.

Exhaust heat content in convective dryers sensible heating of solids heat losses from dryer body. The tangential air distributor of special design introduces the air as an intense swirl flow. Design capacity of both flash dryers is such that it should be possible to build up sufficient dry concentrate stock to stop one flash dryer for a couple of days for maintenance while the furnace and the other flash dryer continue to produce at full capacity.

Dryers - Nutrition and Health Spin Flash Dryers. The simple spin flash dryer is designed to handle materials that can be suspended directly in air. Or FLASH Eav 150 Eav 750 - fair good fair continuous ROTARY 10 30 15 50 indirect Eav 20 Eav 33 - poor good fair continuous ROTARY 20 60 30 100 direct Eav 40 Eav 65 - fair fair good continuous SPIN FLASH 40 18 70 300 Eav 11 Eav 185 - good good fair continuous SPRAY 03 16 5 25.

60 kg of wet product contains 60 x 055 kg water 33 kg moisture and.

4 Spin Flash Dryer From Devahastin S Ed Mujumdar S Practical Download Scientific Diagram

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Springerlink

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Request Pdf

Spin Flash Dryer Triveni Engineering Ahmedabad

Xsg Series Spin Flash Dryer Changzhou Changhang Drying Equipment Co Ltd

1 Simple Flash Drying System Download Scientific Diagram

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Springerlink

0 comments

Post a Comment